Chamber filter plate is a modification of filter plate and frame. Two compacted plates create an individual chamber; filter cake produces on the plates in layer form. As the thickness of the cake increases, the permeability and flow rate decreases causing longer filtration cycles and higher operation costs.

During the later stage of filter cycle, high feed pressure is employed to dry the filter cake and this dewatering period is quite long. This period is usually called non-productive phase.

Chamber filter plates used alone are suitable for general applications where strict requirement of cake dewatering is not high.

However, combination of chamber plate and membrane plate will effectively shorten the filter cycle and save operation cost.

Features

Construction

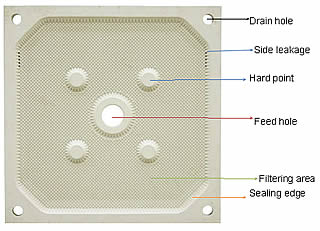

Chamber recessed filter plate is a solid plate. It typically consists of feeding hole, filtering area, drain hole, sealing edge, and hard-point. The number of hard points depends on the thickness of the plate. Feed position is not fixed. Five types of feed position - central, corner, external, head and foot. The sealing edge is machined parallel to seal when the plates are pressurized.

Material

Polypropylene (PP) is a frequent raw material of filter plate. It has chemical inertness, high resistance against oxidation, corrosive media and high temperature, light weight and high strength.

In addition, UHMW-PE and toughened rubber are specially used in harsher environments for their longer service life, excellent abrasion, chemical stabilities and higher compression strength.

Sizes and shapes

Standard sizes: 250, 400, 470, 500, 630, 800, 915, 1000, 1067, 1200, 1300, 1450, 1470, 1500 1500 × 2000 and 2000 × 2000 mm.

Standard shapes: square, rectangle and round.

Larger sizes or different shapes are customized for special orders.

Inquiry for Our Product

Boegger Industech Limited

E-mail: sales@filterplate.org

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.