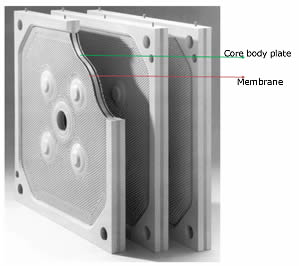

Welded membrane filter plate is the top priority when selecting a filter plate, for it significantly shortens the filter cycle by skipping the non-productive phase of pressure filtration. A couple of welded membrane plates can be used alone or combined with chamber plate. The combination makes full use of each other's advantages. Chamber filter plate is quite effective in the first part of filtration, and during the non-production part, membrane plate will significantly shorten the operation time and reduce the dryness of the cake.

Welded membrane plate is an integral whole, and replaceable membrane plate can be separated into core body and membrane. Due to this character, the whole membrane plate should be replaced whether core body plate or membrane has damaged. This will increase production cost.

Advantages

Materials

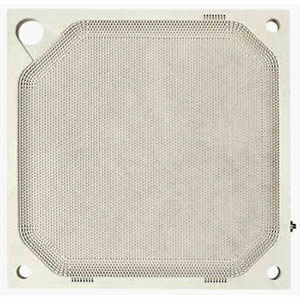

Core body plate can be manufactured by polypropylene, synthetic rubbers such as EPDM, NBR, and TPE (Thermoplastic Elastomers).

Flexible synthetic rubbers are very suitable for difficult and uneven formation of cake.

TPE or thermoplastic elastomer combined the main advantages of polypropylene and rubber, features good mechanical properties and excellent corrosion resistance by heavy metals.

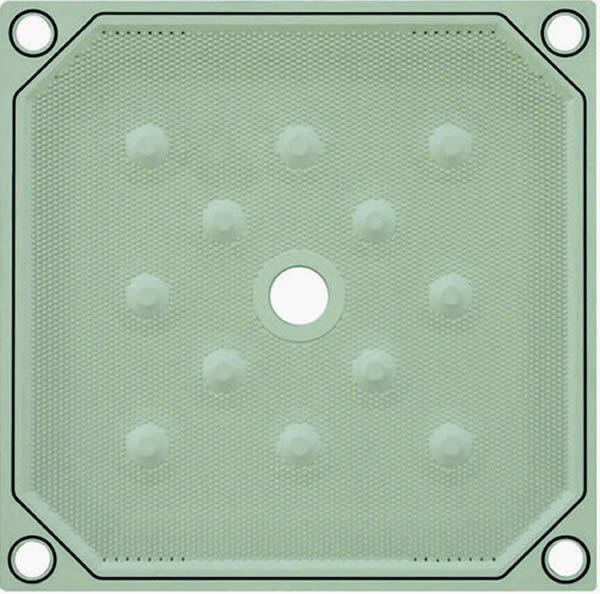

Feed eye

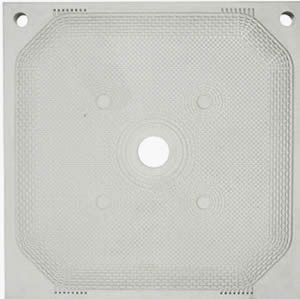

Feed eye positions are often center feed, corner feed, and external feed. Other special feed positions are available for special orders.

Standard Size and shape

Size: 470, 630, 800, 1000, 1200, 1250, 1450, 1500, 1600, 2000 mm in squares.

Shapes can be square, rectangle and round.

Larger or different shapes are available for special orders.

Inquiry for Our Product

Boegger Industech Limited

E-mail: sales@filterplate.org

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.